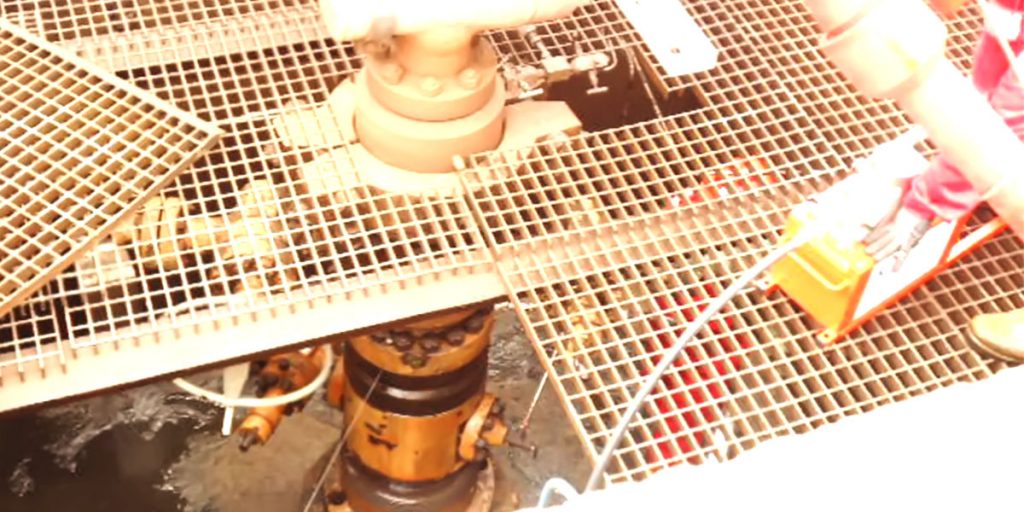

Sealant Deployment Technology

Maintaining wellhead integrity throughout the life of a well while minimising cost and observing no downtime, remains a critical concern during operations. For oil and gas assets to function optimally, there must be a solution for leakage. To achieve this, seals have a major role to play. Equipment such as pumps, valves, flanges, and even pipes must be tightly sealed to avoid pressure escape or any other costly incident.

That is why we use KCI Mac-seal and MS sealant in Sealant Solution Technology to get the desired outcome. At Kenyon, we leverage only the best technologies that are both cost-effective and efficient in optimum job performance.

Pack-off Isolation with MS Sealant

After a well has been producing for a long period of time, there is a possibility of the pack-off seals damaging and leading to communication of pressures between different annuluses. In a case such as this, we employ the use of MS sealant, to enable us isolate pressures from different annulus (e.g., from annulus A to B or vice versa). Doing this enables us to restore the integrity of the pack-off seals while cutting cost as it is a rigless operation.

At Kenyon, we are deliberate about solving technical wellhead problems that affect our clients’ goals.

Void Cavity Isolation

Void Cavity Isolation is often carried when the VG 137 and hanger neck seal and tubing hanger body seal and hydraulic packing seal are unable to hold pressure thereby allowing pressure flow from the wellhead to the void cavity.

In cases like this, we often advise our clients on the best remedy to apply using Mac-Seal or MS-Sealant to seal up the void.

Tubing hanger isolation with MS Sealant

For an effective well completion process, tools like the tubing hanger must be installed appropriately. The tubing hanger is specifically designed to aid completion of oil and gas production wells.

In a case where the tubing hanger’s integrity has been compromised due to severals years of production, its seals become faulty and allows communication of pressure from the annulus to the tubing hanger void cavity. In a situation such as this, we conduct a rigless operation by deploying our sealant technology using MS sealant which is durable enough to prevent such communication of pressures.